Rapid Prototyping

If your engineering or marketing department needs to see the true advantages of your product or if your production group needs to see its workability, Bull can work with your drawing or one that we establish for you to generate samples using a wide variety of processes.

SLA (Stereolithography)

Contact Us- Durable product with high quality detail and surface finishing

- Available resins vary in color, rigidity, clarity and temperature resistance

- Part tolerance ± .005″

- Can be blasted and/or painted for aesthetic detail

- Lead-time of part(s) is usually 3 to 6 working days

- Short-run tooling

SLS (Selective Laser Sintering)

Contact Us- Fine detail and smooth surface finishing – more durable than SLA

- Materials: rigid plastics, rubber-like elastomers and wax-infiltrated patterns

- Part tolerance ± .005″ to .008″

- Capable of producing living hinges, high flex snaps, high stress and heat parts

- Can be finished for presentation, demonstration and photo reproduction

- Lead-time of part(s) is usually 3 to 6 working days

Aluminum Prototype Tooling

Contact Us- Higher quantities of prototypes at relatively lower costs

- Working prototypes with high quality detail

- Properties ranging in rigidity, temperature resistance and color

- Part tolerance within thousandths of an inch

- Capable of high-strength, rubber-like flexibility and moderate temperature tolerance

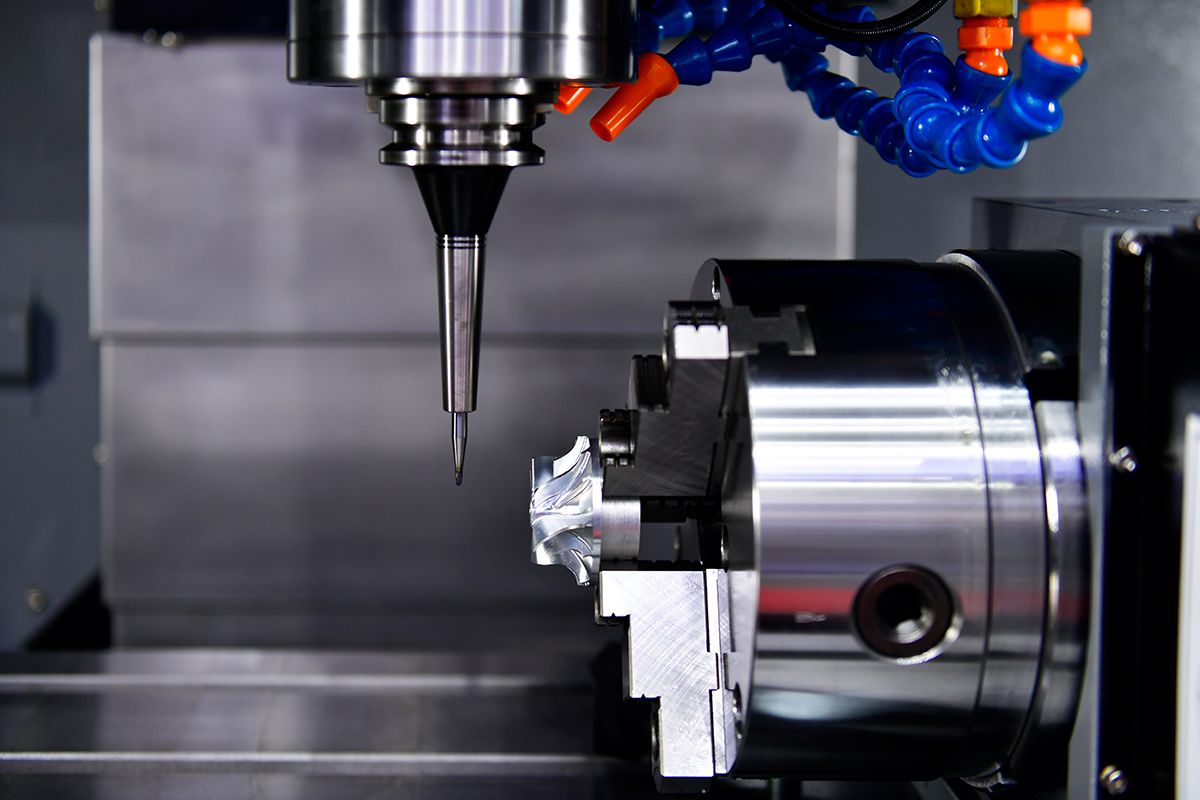

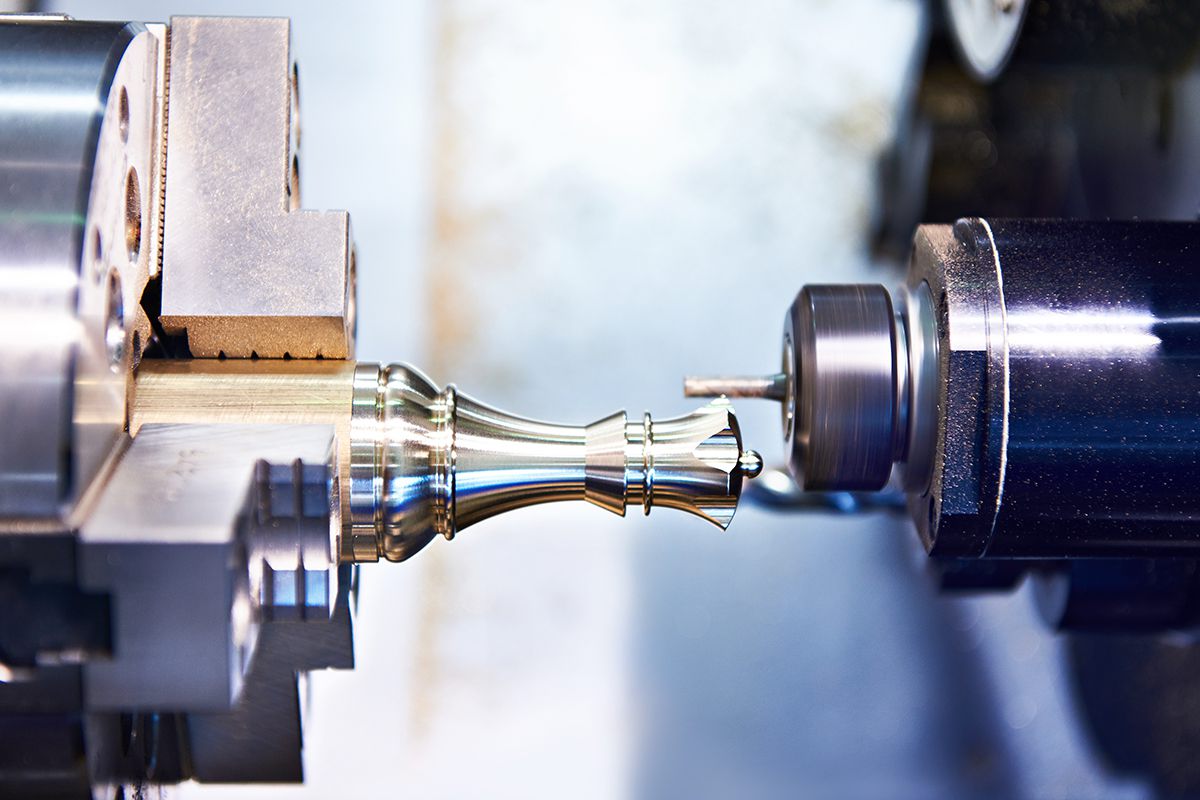

CNC Sheet and Rod Stock

Contact Us- Ability to produce high-detail metal and plastic parts

- Functional metal and plastic parts, prototypes, models, patterns and tooling

- Tight tolerances, sharp detail and good surface finishing

- Inexpensive method of producing simple parts

- Drill, tap and face rapid prototypes to improve detail, accuracy and finish

- Lead-time of part(s) is typically 1 to 2 weeks

Customer peace of mind is our priority.

We achieve this goal through competitive pricing, good lead times and great products.

Lets Talk

Whatever your Rapid Prototyping needs, we've got you covered. Let us show you what we can do together.